- Home

- Manufacturing Equipment

Titan operates 2 production workshops. The first produces our gas powered chainsaws, while the other is used to manufacture the rest of our equipment, including brush cutters, earth augers, hedge trimmers, etc. There are 5 production lines and over 270 workers that include preloading personnel, production line workers, and debugging specialists. Titan utilizes over 10 sets of production and testing equipment, including 8 highly advanced low power testing equipment and 3 injection molding machines.

Negative pressure tester

Function: Testing the inlet volume of the oil pot.

Deflection instrument

Function: Testing the crankshaft beat.

Rockwell hardness tester

Function: Testing the hardness of the mental such as iron and stainless steel

Airtight tester

Function: Testing the sealing performance of the seals

Air gauge

Function: Testing the diameter of the bores the gas cylinders

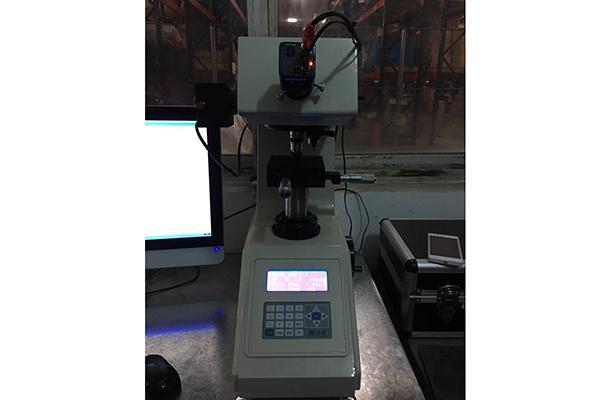

Micro hardness tester

Function: Testing the hardness of the chromium layers

Dynamometer

Function: Testing the machine performance including the power, the fuel consumption, the temperature and the torque.

Air compressor

Function: supplying kinetic energy for the air tools (such as air gun)

Low emission online testing machine PPA

Function: Testing the function of the over-lowed emission(EUII) standard machines

Injection molding machine

Function: Producing plastic parts.

Production process

Material injection test - power assembly - rod assembly - debugging - packaging - complete